TORQtec®

Спецификация

-

Overview

- Individual integration into customer projects

- High degree of efficiency due to press polished thread surface

- Very high efficiency in the production of the parts

- High resistance to wear due to cold-hardened thread flanks

Hotline

Applications Engineer

TORQtec® Motion converter

TORQtec® are EJOT systems, which convert one motion into another. This can be the conversion of one rotary motion into a rotation turned by 90°. Applications can be found in worm gears or spindle-nut-systems. The field of application for the TORQtec® motion converter is versatile. For example in exterior mirror and head rest adjustment systems for cars or spindle adjustments for gas appliances. Versions of the TORQtec® motion converter:

Motion Threads

The advantage of the TORQtec ® System is the cold-formed threaded spindle. The EJOT motion or trapezoidal threads, with a flank angle of less than 30° and a thread flank with very low surface roughness depth, contribute to the lightness of the counterpart.

Spindle-nut-system

Completely cold-formed thread spindles, combined with accurately fitting nuts, preferably made of plastic, with very tight fitting thread pairs characterise these spindle-nut-systems.

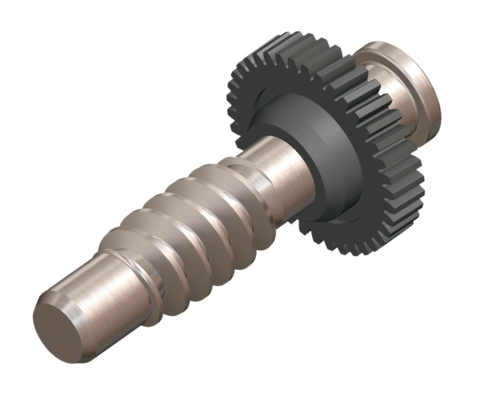

Worm gears

The described cold-forming technology is the basis for worm gear shafts. The thread flanks with very low surface roughness depth, ensure the high degree of efficiency of this system. Cold-forming technology combined with injection moulded gear elements from a single supplier.